EVERYTHING YOU NEED TO KNOW BEFORE ORDERING YOUR CUSTOM LABELS

INKABLE LABEL CO. GUIDE MAP

Your deserve top-quality results, and a stress-free process to match. That’s what you can expect when you work with Inkable Label Co.

With our expert label printing services, you get more than just great prints. You get personalized support at every step.

Beyond exceptional print quality, you’ll have a dedicated team supporting you every step of the way. From free consultations and manual Prepress checks to real-time tracking once your order ships, our Production, Prepress, and Customer Service teams work together to ensure your labels arrive exactly as you envisioned.

We’re committed to delivering top-quality results and making the whole process stress-free for you.

Before we start, we want to make sure you are always 100% satisfied with your experience with us. From free complimentary custom label consultations, to free manual Prepress checks, up until monitoring your package in the post—we’re continuously working hard to deliver perfect custom labels for you.

SERVICE TERMS – Our Custom Label Print Guarantee

We fully guarantee that your custom labels will be free from general printing defects—as long as your artwork follows our file preparation guidelines. If you have any concerns, please notify us within 5 working days of receiving your order.

While our free manual Prepress check helps catch common issues, it’s your responsibility to submit print-ready files. We can’t guarantee results if your file has incorrect bleed, trim setup, or color settings that may cause color shifts during printing.

Need help preparing your file? Please refer to the File Preparation section above or ask your designer for support. If you need hands-on help, we offer file setup services for an additional fee—quoted on a case-by-case basis.

FULFILLMENT AND DELIVERY OF YOUR CUSTOM LABELS

IS MY ORDER ELIGIBLE FOR FREE SHIPPING?

Inkable Label Co. ships custom labels to customers around the globe. While we offer free shipping within the US, international orders may include a postal fee. We’ll always confirm shipping costs with you before processing your order.

HOW LONG WILL IT TAKE FOR MY CUSTOM LABELS TO ARRIVE?

Turnaround Time and Shipping Policy

Production for custom labels begins only after you approve the final proof. Our standard turnaround is 3–5 business days for printing, plus 3–4 days for shipping.

For international customers: Delivery timelines are not guaranteed due to postal and customs variables. If your country isn’t listed at checkout or you’ve had delivery issues before, email us at service@inkablelabel.com with your full address to confirm if shipping is available.

We can commit to pre-agreed completion dates only if all print-ready files and content are submitted the same day the order is placed. Delays in file submission or file issues flagged during Prepress may shift your timeline.

If deadlines aren’t met due to late files or unapproved proofs, delivery dates will need to be adjusted. We’ll always be upfront if we can’t guarantee your requested timeline—moving forward with production means you accept this.

Please Note:

- We are not liable for indirect losses or missed profits due to delivery delays caused by file issues or courier problems.

- However, if any issue occurs outside of industry-standard gang run color shifts, such as printing errors from approved proofs or internal delays, we will offer a full reprint or refund—your choice.

CAN I CHOOSE DIFFERENT SHIPPING LOCATIONS DURING CHECKOUT?

Yes, you can select a different address for each of your custom labels order. Handling and shipping fees may be applicable depending on which locations you nominate.

If you need expedited shipping options, please contact service@inkablelabel.com and we will be happy to arrange this for you.

CUSTOM LABELS SPECIFICATIONS

WHAT LABEL MATERIALS SHOULD I CHOOSE FOR MY CUSTOM LABELS?

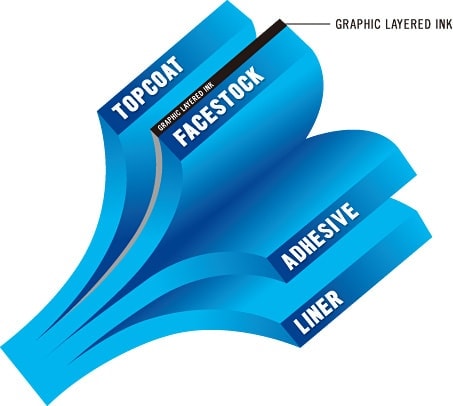

Every custom label starts with a facestock—your base material, which can be either paper or plastic film. The facestock affects durability, print finish, and overall performance, so it’s important to choose the right one for your product’s environment and usage.

When selecting your label material, consider:

- Your desired finish (matte, gloss, natural, etc.)

- The product surface (glass, plastic, metal, etc.)

- The environment (wet, dry, hot, cold, etc.)

- The label’s exposure to moisture, friction, or oil

A good example would be custom water bottle labels. As your labels will definitely, at some point, come in contact with water spillage, you will then need to use something that is more moisture-resistant. A plastic film base with gloss laminate would be best for this type of application to ensure your custom labels have vibrant color, and are *more durable and suited for this particular use.

* The life span of your custom labels is dependent on the label material or facestock that you choose. Paper labels without laminate (uncoated), such as Kraft labels are not waterproof, nor moisture-proof. The addition of a laminate (gloss or matte) will give some protection against moisture, but as the base material or facestock is paper, liquid or moisture can get into the sides and damage the paper base label material.

Your custom labels can be printed on various types of materials, in any size you need. All custom label sizes are available at no extra cost.

DIFFERENT LABEL MATERIAL STOCKS

Paper Labels (Budget-Friendly, For Dry Use)

Great for dry environments and indoor use, paper labels offer excellent print quality at an affordable price.

- Matte Paper – Uncoated white paper for a soft, natural look. Not moisture-resistant.

- Semi-Gloss Paper – Coated white paper for crisp detail with mild resistance when laminated.

- Kraft Paper – Brown, uncoated, eco-friendly paper. Rustic, organic feel. Highly absorbent and not moisture- or oil-resistant.

Optional Laminates:

- Gloss Laminate – Enhances color vibrancy, adds mild protection

- Matte Laminate – Soft satin look, lowers glare

Note: Even laminated paper labels can absorb moisture at the edges.

Plastic Film Labels (Durable, Waterproof)

Ideal for products exposed to water, oil, or friction. These are waterproof, tear-resistant, and offer strong adhesion on smooth surfaces like glass, metal, and plastic.

- White Film – Opaque, bright white base. Durable and flexible with excellent print clarity.

- Clear Film (PVC) – Transparent with a glossy finish. Use white ink underprint for bold, opaque designs.

Recommended for water bottles, cosmetics, food jars, and refrigerated goods.

Foil Labels (Shiny, Budget-Friendly Premium Look)

Foil labels are a cost-effective alternative to foil stamping, offering an eye-catching metallic finish without the high production cost.

- Gold Foil – Glossy mirror-finish gold on a waterproof film base

- Silver Foil (Mirror) – Reflective silver with a plastic film base

- Silver Foil (Dull) – Matte silver on a paper base, not fully moisture-resistant

All foil labels include a gloss laminate for added shine and light moisture protection.

Use foil labels to create a premium look on a budget. Perfect for luxury packaging, limited editions, or branding highlights.

LABEL COATINGS OR LAMINATE

Laminates are coatings on the surface of your custom labels.

Once applied, they create a smoother label texture, and give wear-and-tear protection for your prints against ink scuffing and frequent handling.

This is the top layer of your custom label and this dictates the final look and finish of your custom labels—it is what you can see and feel.

TYPES OF STANDARD CUSTOM LABEL LAMINATES

Custom Labels with Matte Laminate

Matte laminate gives your labels a flat, non-reflective finish with a soft, muted look. Colors appear more subdued, with less contrast and no shine. This finish is ideal for refined, elegant branding and can help mask low-resolution artwork thanks to its low light reflectivity.

Best for: minimalist designs, luxury products, eco-friendly branding

Custom Labels with Gloss Laminate

Gloss laminate creates a high-shine finish that enhances color vibrancy and sharp detail. The smooth surface reflects light, producing brighter highlights and deeper shadows for bold, high-contrast visuals. Gloss also adds extra durability, helping protect against ink scuffing and wear.

Best for: colorful designs, retail packaging, moisture-prone products

* Uncoated paper labels have a “ Matte” finish. It is a term meant to describe uncoated labels and is different from Matte Laminate, which is a non-shine paper coating.

WHAT LABEL FORMAT SHOULD I CHOOSE: INDIVIDUAL LABELS OR ROLL LABELS?

How will you apply your custom labels?

Format is important because it will help make your product packaging process faster.

- Choose roll labels if you’re using a labeling machine or need fast, consistent application. The number of labels per roll depends on your custom label size and material. We can customize the label count per roll on set quantities, but extremely low counts may require realignment and could affect shipping costs.

- Choose individual labels (cut-to-size) if your projects require manual application. Each label is trimmed and stacked for easy handling—ideal for short runs, sample products, or handmade items.

DO I NEED TO SPECIFY THE UNWIND DIRECTION FOR MY ROLL LABELS?

If you’re using a label applicator or labeling machine, yes—you should specify the unwind direction for your custom roll labels. We can print your labels in any orientation you need, whether dispensed up and over (from the top of the roll) or down and under (from the bottom).

Check your machine’s manual or consult the manufacturer to determine the correct unwind direction. This ensures your labels are applied in the right orientation during production.

🖐 If you’re hand-applying your labels, unwind direction isn’t necessary.

⚙️ For high-volume or automated packaging, unwind direction is critical to avoid misalignment or machine errors.

CAN I ORDER CUSTOM LABEL SIZES AND SHAPES?

Yes! At Inkable Label Co., we print custom labels in any size you need—as long as it’s within our standard shape guidelines (from 1″ x 1″ up to 12″ x 18″). All labels are made to measure, and there are no extra charges for custom sizing of standard shapes (a value of up to $350).

If you’re looking for something more unique, we also offer diecut labels—custom shapes that follow the outline of your artwork, like cookie-cutter cutouts. These are finished after printing for a clean, precise look that goes beyond basic geometric shapes.

Diecut labels are perfect for logos, icons, or packaging that needs a standout shape.

DO YOU CUSTOM PRINTING WITH METALLIC INKS?

We currently do not offer this process, as well as foil embossing (raised prints), Spot UV finishing, or Pantone color matching/*Spot color.

We don’t offer metallic ink printing, but we provide a cost-effective alternative using foil labels.

If you need silver or gold effects, we print your artwork on silver or gold foil label stock. By printing color (with a white undercoat) only on specific areas, the untouched portions of the label remain metallic—creating a silver or gold print effect using negative space.

This method mimics metallic printing without the need for foil stamping or special inks.

DO YOU OFFER COLOR MATCHING FOR CUSTOM LABELS?

Yes! If you need accurate color matching, we can convert your file and provide a press proof (hard copy) for review. This ensures your final printed labels meet your color expectations.

See our Proofing section below for more details on press proofs and file prep.

HOW DO I PREPARE MY FILES CORRECTLY FOR PRINT?

To minimize errors, and to make Prepress checks and proofing quicker, please take note of our guidelines below. Taking the time to check and correct any issues below before you submit your file/s to us will make the whole process considerably faster.

CUSTOM LABEL ARTWORK CHECKLIST

FILE SETUP

- Set all your label artwork’s images, objects, and your file’s colour mode to CMYK for digital printing.

- We print labels to any size. Please double check artwork dimensions before sending to save on proofing time.

- Do not include printer’s crop marks or registration marks in your PDF export.

- Add a 3mm bleed to all sides.

ARTWORK

- Our Prepress check does not include reviewing text. We do not alter textual content to keep the integrity of the files, especially with sensitive information (contact numbers, names, alphanumeric codes, and so on), to avoid any clerical errors. It is your responsibility to check for spelling and/or grammar mistakes and correct these accordingly.

- We strongly recommend that all raster images be at least 350 dpi (original resolution, not resized) to ensure that your artwork prints sharp, without any pixilation.

- Outline all fonts. This is important in your free Prepress check and report, because any errors in layout area, color saturation or other preflight concerns will entail touching these art elements. We cannot correct issues with flattened layers.

- If there are any fine lines in your label artwork, please note that the minimum line thickness that our machine can go down to is .57pt or 0.2mm. Any thinner and we cannot guarantee strong, even printed lines.

FILE NAMING

While our customer service associates will be on hand to manage your custom label projects, proper file naming is important as an initial measure to make processing faster, and so that we can easily track and annex files related to your print job.

Please use this naming scheme for all your label artwork files:

Your Company Name – Name of Label – Date

FILE FORMATS

Please save your label artwork as layered .PDF files so that our Prepress Team can properly check and report any issues to you.

We can certainly work with layered files saved as one of the below formats as well :

- PDF (Adobe Portable Document File)

- TIFF (Tagged Image File Format)

- EPS (Encapsulated PostScript)

- AI (Adobe Illustrator Artwork)

- PSD (Adobe Photoshop Artwork)

We prefer to use PDF files whenever possible for our Prepress checks. If you submit a file in any other format, we cannot process this and you will need to convert them into one of the above formats.

COLOR SETTINGS

Please set your label artwork’s objects, images, colors within the document, as well as the document’s color settings to CMYK (Cyan – Magenta – Yellow – black color space) for digital printing. Any files submitted in RGB color space will be automatically converted to CMYK, resulting to a slight color shift. We cannot guarantee color integrity from converted files.

* We do not color-correct artwork. Any and all color values on the layout will also be respected and this will remain untouched unless artwork exceeds the recommended TIC (Total Ink Coverage), in which we will need to reduce ink saturation to avoid print issues. In this case, we will report this to you as certainly there will be a color shift resulting to the adjustment made.

PMS (PANTONE MATCHING SYSTEM) COLORS : We do not offer Spot Color matching at this time. Our digital printing uses a four-color process build (CMYK); and while we can’t guarantee very close color replication, we can make an approximation by converting color values to close CMYK combinations.

* An important note : Comparing color on screen is not a good benchmark for color accuracy, as our screens are calibrated differently. If you are keen on getting very close color, we offer hard proofs as well, so that you can personally check for color accuracy. This is provided at a minimal fee.

IMAGE QUALITY

WHAT IMAGE QUALITY DO I NEED FOR CUSTOM LABEL PRINTING?

Image quality is critical for high-quality custom label printing. One of the most important things to check before submitting your file is the resolution—both the overall file and each individual element (images, text, shapes).

We strongly recommend setting all artwork and images to 350 DPI (dots per inch). Files below this may print blurry or pixelated. If you’re using original design files, all elements must also be 350 DPI or higher to prevent quality loss.

File Prep Tips for Best Results:

- Set full file and individual images to 350 DPI

- Use vector format (AI, PDF, EPS) for text, logos, and shapes

- Avoid rasterized fonts or low-res JPEGs

- TIFF files without JPEG compression are ideal for photos

- If using JPEGs, they must be original files at 350 DPI, not resampled or upscaled

⚠️ We cannot guarantee print quality if your file includes low-resolution images or non-vector text. If we detect low-res elements, we’ll ask you to resupply the correct files—we can’t recreate what isn’t already there.

Need help checking your file? We offer a free manual Prepress check to catch resolution and layout issues before printing.

SAFETY MARGINS, BLEED, AND TRIM

WHAT ARE BLEED, SAFETY MARGINS, AND TRIM LINES IN MY LABEL PROOF?

When reviewing your custom label proof, you’ll see colored guidelines that help ensure your design prints correctly:

- Red Lines = Bleed Area

This is the outer edge where your design should extend beyond the final cut size. Any background colors or images meant to go edge-to-edge should reach this red line.

➤ Add 1/8 inch (0.125″) bleed on all sides to avoid white edges after trimming. - Blue Lines = Safety Margin

Keep all important elements (like logos and text) within this inner blue box to ensure they don’t get trimmed off during cutting. - Black Lines = Final Trim Size

This represents the finished size of your custom label—what you’ll receive after trimming.

* We require files to have the correct Bleed ad Safety settings, otherwise this will double proofing time.

If you do not follow our requirements above, we cannot guarantee and will not be responsible for the outcome of your final printed labels.

MINIMUM ORDER QUANTITY

WHAT IS THE MINIMUM ORDER QUANTITY FOR CUSTOM LABELS?

Our minimum order quantity for custom labels is 1,000 pieces. This allows us to process and print your labels efficiently, keeping production costs low and passing the savings on to you.

The more you order, the more you save—higher quantities unlock better pricing per label unit.

PROOFING OF YOUR CUSTOM LABELS

TYPES OF PROOFS

“SOFT” PROOFS OR DIGITAL (ON-SCREEN) PROOFS : For every label artwork that is provided with every custom label order, we provide complimentary Prepress checks and soft proofs. This is free of charge. You can sign off on the soft proofs if color is not critical. These are accurate enough that they confirm layout, ink saturation issues, and text/grammar issues.

“HARD” PROOFS OR PRINTED PREPRODUCTION PROOFS (PRESS PROOFS) : These are finished printed sample labels that will show you how your artwork will look like on the actual material you specified, using the same inks, as on your approved soft proof. These will allow you to have a look-feel, and you can peel away the backing paper and apply these on your products, for a final review, before we start production of the whole lot.

These are provided at a small fee, for projects that need closer color reproduction, or a signed approval from your team. Press proofs will take a week (including shipping); please plan your timelines accordingly if you require these.

REORDERING YOUR CUSTOM LABELS

HOW CAN I RESUPPLY MY ARTWORK?

We keep all files that we have printed for all our customers’ projects. This includes approved soft proofs that have been sent to press.

If you would like to reorder your custom labels, you can simply email us at service@inkablelabel.com and specify your job number in the email subject line.

CAN I SEE A PROOF OF MY PRINTED LABELS SO THAT I CAN RE-CHECK?

Certainly, we’ll be happy to re-send your soft proof and we do recommend double-checking before reprinting your custom labels. Simply email your request to us at service@inkablelabel.com and reference your order number. We’ll send you a soft PDF proof as soon as possible.

PAYMENT PROCESS

WHAT ARE THE DIFFERENT WAYS I CAN PAY FOR MY CUSTOM LABELS ORDER?

Visa, Mastercard, Bank Card, through PayPal (You do not even need a PayPal account as long as you have a working credit card), and PayPal Prepaid.

DO YOU RETAIN CREDIT CARD INFORMATION?

We take our online payment security very seriously, and for this reason we will never store credit card information on our servers. Any and all personal information is kept strictly confidential.

All online payments are made through PayPal merchant services. What this means is that we never see your personal details, or your card details at all. The only information we see is whether or not the payment has been approved or declined.

THE INKABLE LABEL CO. GUIDE MAP is a quick and comprehensive resource to help you understand the processes that will conduct you throughout your custom label ordering process.

Everything is dedicated to increasing your confidence in shopping with us, and ensuring you are empowered with correct information before you head out to print your custom labels.